Durable Flexible Gear Couplings for Heavy-Duty Power Transmission.

We specialize in manufacturing precision Flexible Gear Couplings engineered to handle the highest torque demands and substantial shaft misalignment in critical industrial machinery. Designed as a mechanical connection between rotating shafts, our gear couplings ensure reliable, efficient power transfer, even under punishing operational conditions.

Understanding Gear Couplings: High Torque, High Reliability

Though the term "gear" implies rigidity, these advanced devices function as a high-performance flexible coupling. They consist of two hubs with crowned external teeth and two outer sleeves with internal spur teeth. This robust gear mesh allows the coupling to transmit maximum power while compensating for axial float, angular, and parallel misalignment.

Our commitment to fine tolerance machining ensures proper meshing, exceptional torsional stiffness, and complete interchangeability of components, making us a leading Gear Couplings Manufacturer in Pune and across India.

Core Benefits of Our Flexible Gear Couplings

Optimize your machine performance and minimize costly downtime with features engineered for endurance:

- Exceptional Torsional Stiffness: Ensures immediate and positive power transmission, crucial for consistent machine cycles and precise operations.

- Very High Torque Density: Transmits significantly more torque compared to most other coupling types for the same diameter, optimizing space and weight.

- Misalignment Compensation: Accommodates a moderate degree of shaft misalignment (up to 3° in some configurations) and substantial end float.

- Vibration Damping: Used effectively in motion control systems to reduce operational noise and dampen machine vibration (especially with polymer-sleeved options).

- Durable & Long-Life: Mechanized to fine tolerances from highly durable materials, ensuring prolonged service life and good reliability when properly maintained.

Choosing the Right Gear Coupling Type

We supply gear couplings in both standard industry variations to suit your specific drive requirements:

Full Flexible Gear Couplings:

Also known as double engagement forged steel couplings. This is the most common industrial choice, compensating for both parallel shaft misalignment and angular misalignment, and offering large end float capacity. Ideal for connecting two flexible halves across a significant distance.

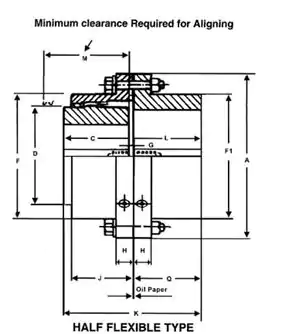

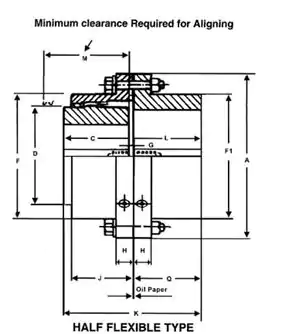

Half Flexible Gear Couplings:

Comprises one flexible half (internal sleeve and inner hub) connected to a rigid half (flanged hub). These are typically utilized to connect a floating shaft to a rigidly mounted machine component, such as a flywheel or brake drum.

| COMMON FOR BOTH COUPLING | FULL FLEXIBLE TYPE | HALF FLEXIBLE TYPE | ||||||||||||||||||||

| H.P Cap | ||||||||||||||||||||||

| at | MAX | |||||||||||||||||||||

| DSC | 100 | TORQUE | MAX | BORE | BORE | J | B | WR2 | Wt. | BORE | WR2 | Wt. | ||||||||||

| G.C. NO | R.P.M. | Kg. M. | R.P.M. | MIN | A | C | D | F | M | G | H | MAX | KGM2 | in Kg. | K | Q | MAX | F1 | KGM2 | in Kg. | ||

| GC-100 | 7 | 50 | 8000 | 10 | 120 | 45 | 50 | 75 | 55 | 1.5 | 15 | 32 | 40 | 93 | 0.03 | 4.5 | 93 | 46.5 | 45 | 70 | 0.04 | 5 |

| GC-101 | 14 | 100 | 6300 | 20 | 170 | 55 | 65 | 110 | 65 | 2.5 | 17 | 45 | 49 | 115 | 0.14 | 11 | 115 | 57.5 | 60 | 85 | 0.15 | 11 |

| GC-102 | 35 | 250 | 5000 | 30 | 185 | 70 | 85 | 125 | 80 | 2.5 | 17 | 60 | 62 | 145 | 0.2 | 15 | 145 | 72.5 | 75 | 110 | 0.24 | 15 |

| GC-103 | 63 | 450 | 4000 | 40 | 220 | 85 | 150 | 150 | 105 | 2.5 | 20 | 75 | 78 | 175 | 0.48 | 25 | 175 | 87.5 | 90 | 130 | 0.5 | 20 |

| GC-104 | 119 | 850 | 3350 | 50 | 250 | 105 | 130 | 175 | 125 | 2.5 | 20 | 90 | 96 | 215 | 0.95 | 39 | 215 | 107.5 | 110 | 160 | 1 | 40 |

| GC-105 | 182 | 1300 | 2800 | 60 | 290 | 110 | 155 | 200 | 140 | 5 | 25 | 110 | 106 | 230 | 1.9 | 57 | 230 | 115 | 130 | 185 | 2 | 60 |

| GC-106 | 280 | 2000 | 2500 | 75 | 320 | 125 | 175 | 230 | 155 | 5 | 25 | 125 | 117 | 260 | 3 | 85 | 260 | 130 | 150 | 215 | 3.3 | 80 |

| GC-107 | 490 | 3500 | 2100 | 90 | 350 | 140 | 205 | 260 | 175 | 5 | 25 | 140 | 134 | 290 | 5.25 | 103 | 290 | 145 | 170 | 240 | 5.8 | 106 |

| GC-108 | 630 | 4500 | 1900 | 105 | 380 | 155 | 230 | 290 | 190 | 5 | 25 | 160 | 147 | 320 | 8.5 | 138 | 320 | 160 | 200 | 285 | 9.5 | 149 |

| GC-109 | 784 | 5600 | 1700 | 125 | 430 | 165 | 250 | 330 | 205 | 5 | 27 | 180 | 156 | 340 | 15 | 210 | 340 | 170 | 220 | 315 | 16.8 | 170 |

| GC-110 | 1148 | 8200 | 1400 | 140 | 490 | 180 | 310 | 390 | 220 | 5 | 27 | 220 | 171 | 370 | 30.5 | 277 | 370 | 185 | 260 | 370 | 35 | 264 |

| GC-111 | 1536 | 11000 | 1250 | 160 | 545 | 200 | 350 | 445 | 240 | 5 | 30 | 260 | 192 | 410 | 58 | 550 | NOTE | |||||

| GC-112 | 2053 | 14700 | 1120 | 180 | 590 | 240 | 400 | 490 | 280 | 5 | 30 | 300 | 231 | 490 | 88 | 710 | 1. Made to order / special Gear | |||||

| GC-113 | 2793 | 20000 | 1000 | 200 | 680 | 260 | 440 | 555 | 310 | 7.5 | 35 | 330 | 242 | 535 | 138 | 980 | Couplings also can be Manufactured | |||||

| GC-114 | 3994 | 28600 | 900 | 220 | 730 | 280 | 500 | 610 | 330 | 7.5 | 35 | 370 | 266 | 575 | 291 | 1320 | 2. Synamic Balancing & heat treatment | |||||

| GC-115 | 4852 | 34750 | 800 | 250 | 780 | 320 | 540 | 660 | 370 | 7.5 | 35 | 410 | 305 | 655 | 353 | 1700 | will be done on request | |||||

Transmits maximum horsepower (HP) in a compact size, making selection easier.

Designed to operate smoothly even with up to 1.5° of angular misalignment.

Precision-generated gear teeth ensure uniform contact and reduce stress on connected equipment.

Available to suit various machine configurations (floating shaft or rigid end).

- EOT Crane Power Transmission (due to frequent forward/reverse applications and high torque)

- Pumps, Blowers, and large Compressors

- Heavy-duty Mixers and Agitators

- Large Industrial Machines requiring high rigidity and continuous torque transmission.

We combine decade-long experience, precision manufacturing, and responsive after-sales support to deliver couplings that minimize downtime and maximize life.