Precision Torque Limiter Couplings: The Mechanical Fuse for Overload Protection.

As a leading supplier of safety-critical drivetrain components, we manufacture robust Torque Limiter Couplings designed to act as a mechanical fuse. This friction-based, automatic device is essential for protecting expensive mechanical equipment from catastrophic damage caused by sudden torque overloads, jams, or crash stops.

By preventing excessive torque from reaching your driven components, our limiters safeguard both your machinery and your continuous production processes.

Our Torque Limiters and Couplings protect machinery by disengaging the drive when torque exceeds preset values, preventing costly damage. As a trusted manufacturer & supplier of torque limiter couplings, we design them for accuracy, safety, and durability.

Torque Limiters

S.S. Torque Limiters is a protective device that limits torque transmitted in a drive systems by slipping when torque demand exceed a preset value as a result of shock loads, over loads or machine jams. It automatically reengages when the overload torque has passed, no resetting is required. The S.S. Torque Limiter prevents machines damage and eliminates costly downtime . The S.S. Torque Limiter utilizes spring loaded friction surfaces for its operations, slip torque is presets by adjustment of the spring force. The S.S. Torque Limiter can be used with a sprocket, gear, sheave or flange plate as centre member that is clamped between two friction liners.

Torque Limiter Couplings

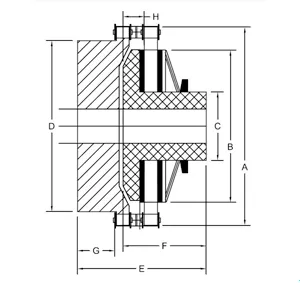

We offers a Torque Limiter Couplings in 14 sizes. This device consists ofa stock Torque Limiter and a roller chain type coupling. The Torque Limiter Coupling combines overload slip-protection with the ability to couple driving and driven shafts. It is an assembly consisting of a standard Torque Limiter and a Roller Chain Coupling. A stock ground plate sprockets serve as the centre member of the Torque Limiter, and it is coupled to a sprocket by an I.S. double stand roller chain which in easily connected by a standard connecting link. This construction provides a dependable and easy-to-assemble flexible coupling having shaft misalignment compensation.

How Our Torque Limiting Couplings Prevent Catastrophic Failure

Our design operates on a simple, friction-based theory, ensuring jerk-free engagement and disengagement:

- Automatic Overload Detection: The limiter acts as a 1:1 transmission under normal operating conditions.

- Instant Disengagement: When the torque load surpasses a specified, pre-set value (due to a jam or overload), the coupling immediately disconnects the driving shaft from the driven system by slipping on a friction disc or uncoupling the load entirely (similar to a shear pin mechanism).

- Energy Dissipation: This rapid disengagement shuts down the machine and allows the rotating inertial energy to dissipate safely, preventing excessive damage to critical components like gearboxes, motors, and shafts.

- Protection at Low Speeds: They are also critical for systems that can develop unnecessarily large amounts of torque at very low operating speeds.

Key Features of Our Torque Limiters Design

Investing in our torque limiting system provides several distinct operational advantages:

- Friction-Based Reliability: Provides reliable, repeatable protection without the need for constant adjustment.

- Safety Mechanism: Acts as a critical safety device, limiting damage and maximizing machine uptime.

- Automatic Operation: Automatically disconnects the motor when a jam occurs (e.g., in a conveyor system), preventing further damage.

- Simple Integration: Designed to integrate seamlessly into existing drivetrain systems.

Critical Applications for Torque Limiters

Torque limiter couplings are a necessity in any machine where unexpected blockages or shock loads are possible. They are widely used across the following industrial sectors:

- Material Handling: Essential for Conveyors and Assembly Lines.

- Packaging: Protecting high-speed packaging machinery from jams and misfeeds.

- Robotics: Safeguarding industrial robots from damage when encountering unexpected obstacles.

- Processing: Utilized in Printing and Converting Machines, Woodworking, and Textile Machinery.

- Sheet Metal & Tooling: Integrated into machine tools and sheet metal processing equipment.

- Motor Drives: Used with servo and DC motor drives to protect against inertial spikes.

| Torque Limiter Size | Torque Capacity (KG. M.) | Pilot Bore (mm) | Approx. Wt. Kg. | A | B | C | D | M. Max. | 'F' Sprocket Bore Dia. Over Bushing | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Min. | Max. | Min. | Max. | ||||||||

| 50-M1 | 0.3 | 1.5 | 8.0 | 14 | 0.3 | 50 | 29 | 24 | 4 | 7.2 | 30.10 |

| 50-M2 | 0.6 | 2.5 | 8.0 | 14 | 0.3 | 50 | 29 | 24 | 6.5 | 7.2 | 30.10 |

| 65-M1 | 0.7 | 2.8 | 10.0 | 22 | 0.5 | 65 | 50 | 35 | 15 | 8.8 | 41.40 |

| 65-M2 | 1.4 | 5.5 | 10.0 | 22 | 0.5 | 65 | 50 | 35 | 15 | 8.8 | 41.40 |

| 90-M1 | 2.0 | 7.0 | 12.0 | 28 | 1.5 | 90 | 65 | 45 | 18 | 16.0 | 52.00 |

| 90-M2 | 3.5 | 14.0 | 12.0 | 28 | 1.5 | 90 | 65 | 45 | 18 | 16.0 | 52.00 |

| 125-M1 | 5.0 | 18.0 | 15.0 | 38 | 3.5 | 125 | 78 | 60 | 23 | 16.0 | 70.00 |

| 125-M2 | 6.5 | 36.0 | 16.0 | 38 | 3.5 | 125 | 78 | 60 | 23 | 16.0 | 70.00 |

| 150-M1 | 7.5 | 44.0 | 20.0 | 42 | 5.5 | 150 | 90 | 70 | 26 | 23.0 | 80.00 |

| 150-M2 | 9.0 | 61.0 | 20.0 | 42 | 5.5 | 150 | 90 | 70 | 26 | 23.0 | 80.00 |

| 180-M1 | 11.0 | 58.0 | 25.0 | 64 | 10.0 | 180 | 110 | 100 | 28 | 28.5 | 110.00 |

| 180-M2 | 20.0 | 110.0 | 25.0 | 64 | 10.0 | 180 | 110 | 100 | 28 | 28.5 | 110.00 |

| 225-M1 | 22.0 | 140.0 | 25.0 | 92 | 20.0 | 230 | 120 | 140 | 33 | 28.5 | 152.00 |

| 225-M2 | 40.0 | 175.0 | 25.0 | 92 | 20.0 | 230 | 120 | 140 | 33 | 28.5 | 152.00 |

We offer adjustable torque settings, compact profiles, and optional remote-reset mechanisms for efficient plant operation.