High-Precision Spur Gears and Bevel Gears for Optimal Power Transmission.

As a leading Manufacturer and Supplier of Spur Gears and Bevel Gears, we provide the fundamental mechanical components required for reliable and efficient power, torque, and speed transfer in modern machinery. Our gears are engineered for exceptional durability, precision, and performance, ensuring consistent motion control across all industrial demands.

Every gear undergoes strict quality checks, conforming to global standards for strength, accuracy, and prolonged service life. We supply a wide range of sizes, widths, and dimensions to meet your distinct design requirements.

Our Spur Gears and Bevel Gears are crafted with precision cutting and heat treatment to ensure maximum strength and efficiency. As a dedicated supplier & manufacturer of gears, we provide high-performance gear solutions for diverse industries.

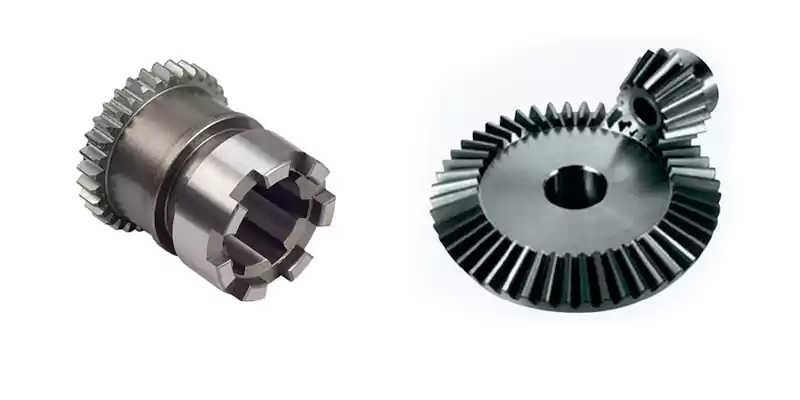

Spur Gears: Efficiency for Parallel Shaft Power Transmission

Spur Gears are the most common and simplest gear type, known for their high efficiency and robust performance.

- They feature straight teeth cut around the edge of a cylindrical body.

- Designed exclusively for parallel shaft configuration—they must be fitted on shafts aligned on the same plane.

- High Efficiency: Minimize friction for smoother, more efficient power transfer.

- Robust Design: Capable of handling high speeds and high loads.

- Simple Alignment: Best for applications where shafts are parallel.

- No Thrust Force: Their straight-tooth design avoids generating axial thrust forces, simplifying mounting.

- Versatility: Can be paired with other spur gears, internal gears, or gear racks.

Bevel Gears: Torque Control for Intersecting Shafts

Bevel Gears are indispensable when power transmission requires a change in the direction of motion, typically at a 90° angle.

- They are shaped like a truncated cone, with teeth designed to interlock on axes that intersect.

- They can connect shafts perpendicularly or at any specified angle, offering unique design versatility.

- Intersecting Axis Configuration: The primary solution for changing the rotational direction of a shaft.

- Torque/Speed Adjustment: Remarkable ability to increase torque and decrease speed between perpendicular rotating shafts.

- High Efficiency: Highly efficient for a wide range of demanding applications.

- Types: Available in Straight, Spiral, Zeroil, and Hypoid designs to optimize performance characteristics.

We follow strict quality checks including gear tooth inspection, material certification, and runout tests to deliver gears that last.