Roller Chain Couplings: Compact, High-Torque Solutions for Mechanical Power Transmission

Our Roller Chain Couplings are a highly effective and robust solution for connecting shafts in industrial equipment. Composed of two forged, hardened sprockets connected by a durable double-strand roller chain, this coupling design is simple yet powerful, making it exceptionally effective for low-speed, high-torque applications where durability and cost-effectiveness are priorities.

Our Roller Chain Couplings offer a simple and cost-effective method to transmit torque between shafts. Designed with hardened sprockets and double roller chains, they are ideal for rugged industrial environments. As an experienced manufacturer & supplier of roller chain couplings, we ensure consistent quality and long service life.

This simple and reliable design offers several key operational benefits across a wide range of machinery:

- Cost-Effective Power Transmission: Chain couplings are renowned for providing an economical way to transmit significant power between shafts.

- High Torque Capacity in a Compact Size: The torque is distributed across the entire roller chain and all sprocket teeth, allowing the device to transmit a high amount of torque despite its comparatively small and lightweight construction.

- Tolerance for Misalignment: The inherent clearance created between the roller chain and the sprockets provides the flexibility needed to accommodate minor angular and parallel misalignment between shafts.

- Easy Installation and Maintenance: The single-pin design allows the chain to be uninstalled and reinstalled quickly using a connecting pin, minimizing labor and reducing machine downtime.

For demanding applications and extended service life, we strongly recommend adding our Cast Aluminum Covers:

- Continuous Lubrication: Covers are designed to be filled with a good quality ball bearing grease, ensuring continuous lubrication of the chain and sprockets.

- Full Protection: Provides full protection from dust, abrasive elements, and environmental contaminants, significantly extending the life of the coupling components.

- Safety and Design: The casing revolves with the coupling body, eliminating dangerous projecting bolts and offering a clean, attractive design.

Due to their simplicity and high-torque capability, chain couplings are utilized widely in sectors where mechanical power transmission is critical:

- Conveyors and Material Handling: Used extensively for reliable power transfer in conveyor belt systems.

- Industrial Machinery: Employed in printing presses, wire- and tube-drawing machines, and heavy press machines.

- Agricultural Equipment: A common and dependable choice for various agricultural machinery.

Choosing the correct size is crucial for coupling longevity and performance. Follow these steps for accurate selection:

- Determine Design Horsepower (HP): Multiply the horsepower of the driver unit by the appropriate service factor, based on hours of service (e.g., use a higher factor for 16-24 hour service).

- Verify RPM: Note the maximum rotational speed (RPM) of the shaft.

- Check Bore Diameter: The coupling size selected must be rated equal to or slightly greater than the Design H.P. at the operating RPM, and the shaft diameter must be less than the maximum permissible bore.

- Conveyors, crushers, mixers

- Machine tools and heavy-duty industrial drives

- Agricultural and material handling systems

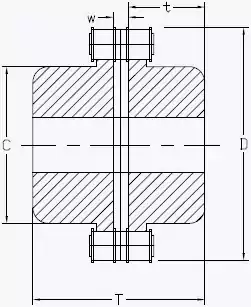

| Coupling Size | Bore | T | t | W | C | D | Wt.Kg. | |

|---|---|---|---|---|---|---|---|---|

| Min. | Max. | |||||||

| CC3812 | 10.00 | 16 | 65 | 30 | 5.0 | 27 | 45 | 0.30 |

| CC4012 | 10.00 | 22 | 79 | 36 | 7.0 | 35 | 60 | 0.80 |

| CC4016 | 12.00 | 32 | 79 | 36 | 7.0 | 50 | 77 | 1.60 |

| CC5016 | 16 | 42 | 96 | 44 | 8.0 | 61 | 96 | 2.60 |

| CC5016 | 16 | 48 | 98 | 45 | 8.0 | 71 | 106 | 3.50 |

| CC6018 | 20 | 60 | 121 | 56 | 9.0 | 88 | 126 | 6.5 |

| CC6022 | 20 | 76 | 121 | 56 | 9.0 | 110 | 150 | 10.0 |

| CC8018 | 25 | 80 | 150 | 67 | 16 | 115 | 170 | 14.5 |

| CC8022 | 25 | 95 | 150 | 67 | 16 | 140 | 201 | 20.0 |

| CC10020 | 40 | 110 | 200 | 91 | 18 | 157 | 231 | 33.5 |

| CC12018 | 50 | 119 | 260 | 118 | 24 | 169 | 254 | 51.0 |

| CC12022 | 50 | 150 | 260 | 118 | 24 | 208 | 301 | 76.0 |

| CC16018 | 50 | 160 | 360 | 165 | 30 | 220 | 341 | 121.0 |

| CC16022 | 50 | 199 | 360 | 165 | 30 | 280 | 410 | 210.0 |

| CC20018 | 60 | 205 | 517 | 240 | 37 | 295 | 425 | 320.0 |

| CC20022 | 60 | 260 | 517 | 240 | 37 | 373 | 507 | 470.0 |

We provide durable chain coupling kits, spare parts, and on-demand custom sprocket profiles for seamless field replacement.