Flexible Jaw Couplings: The Industry Standard for Vibration Damping and Fail-Safe Operation

As the industry's standard shaft coupling, our Flexible Jaw Couplings are engineered for seamless power transmission in light to medium-duty applications. Designed for reliability and ease of use, these couplings utilize a highly resilient elastomeric element (the spider) that effectively dampens shock loads and minimizes system vibrations, protecting your valuable rotating equipment.

As a leading supplier and manufacturer of jaw couplings, we provide solutions that reduce maintenance costs and extend machine life.

Key Advantages of Our Jaw Coupling Design

Our design ensures longevity and performance with minimal upkeep, making them the preferred choice for industrial motors, pumps, and gearboxes:

- Fail-Safe Assurance: In the unlikely event of spider failure due to extreme wear or overload, the driving jaws and driven jaws interlock, maintaining continuous operation and preventing unexpected downtime.

- Superior Shock and Vibration Absorption: The elastomer element provides an effective cushion, significantly reducing torsional oscillation and mechanical noise.

- Zero-Maintenance Operation: Our flexible jaw couplings require absolutely no lubrication. They feature no metal-to-metal contact during normal operation, eliminating wear.

- High Resistance to Contaminants: The robust material construction is inherently resistant to common industrial contaminants, including oil, dirt, sand, moisture, and grease.

- Misalignment Tolerance: Effortlessly accommodates angular and parallel shaft misalignment, protecting the life of bearings and seals on connected shafts.

Available Materials and Configurations

We offer one of the industry's largest selections of flexible jaw couplings to meet diverse environmental and load requirements:

- Hub Materials: Available in multiple combinations (e.g., Cast Iron, Aluminum, Bronze, or Steel) to match strength and weight requirements.

- Elastomer Spiders: Available in different durometer ratings (hardness) and materials (such as NBR, Urethane, or Hytrel) to tune the coupling for torque capacity and vibration damping.

- Inventory: We maintain the industry's largest available stock selection, ensuring rapid availability for replacement or new installations.

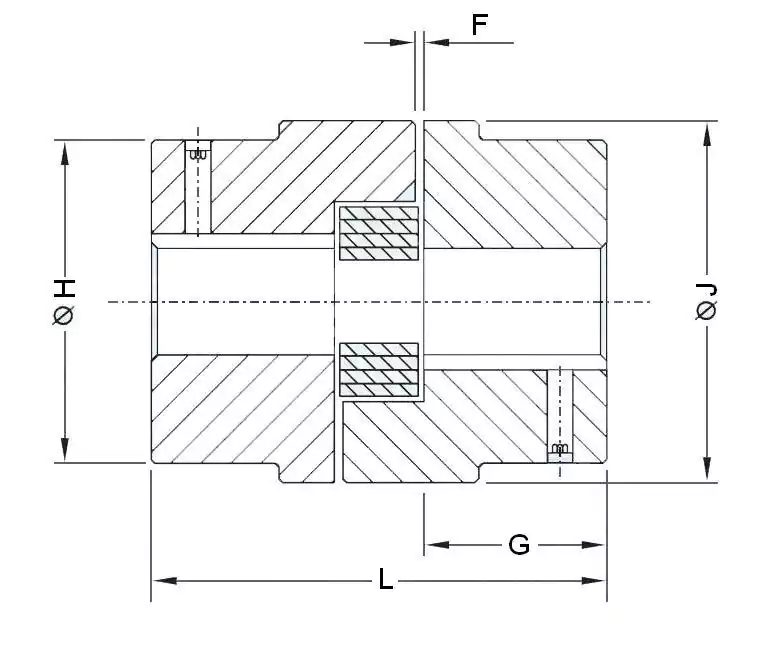

| TYPE | SIZE | Rated Hp | Rated | BORE SIZE | Weight** | Jaw | Ring | Total | Hub | Length | Length | Spacer Length | Gap.Bet | Bolt | Dist | ||||

| Torque | ØP | Kg CI-Pilot | Dia | Dia | Length | Dia | Through | Of | Jaw | Exten | Between | ||||||||

| 1000 | 1500 | 3000 | Kg-m | Bore | Bore | Bush | & Body | Shafts | |||||||||||

| rpm | rpm | rpm | Pliot | Max | Coup | ØJ | ØR | L | ØH | G | B | S | F | X | D*** | ||||

| S | 50 | 0.3 | 0.5 | 0.9 | 0.21 | 5 | 16 | 0.24 | 27 | - | 42 | 27 | 15 | - | - | 1 | - | 12 | |

| 70 | 0.5 | 0.8 | 1.5 | 0.35 | 9 | 20 | 0.28 | 36 | - | 51 | 36 | 19 | - | - | 2 | - | 13 | ||

| 75 | 1.0 | 1.5 | 3.0 | 0.71 | 9 | 22 | 0.45 | 44.5 | - | 56 | 39 | 21 | - | - | 2 | - | 14 | ||

| S | 95 | 2.8 | 4.2 | 8.4 | 2.00 | 10 | 28 | 0.8 | 54 | 64 | 63 | 49 | 25 | 25 | 75/90/100/140 | 2 | 15 | 13 | |

| SR | 99 | 4.0 | 6.0 | 12.0 | 2.86 | 10 | 30 | 1.10 | 65 | 77 | 72 | 51 | 27 | - | - | 2 | - | 18 | |

| SE | 100 | 6.0 | 9.0 | 18.0 | 4.29 | 10 | 38 | 1.50 | 65 | 77 | 88 | 57 | 35 | 30 | 75/90/100 | 3 | 15 | 18 | |

| SRE | 110 | 11.0 | 16.5 | 33.0 | 7.87 | 15 | 42 | 3.20 | 85 | 96 | 108 | 76 | 43 | 35 | 135/140 | 3 | 20 | 22 | |

| SN | 150 | 17.0 | 25.5 | 51.0 | 12.17 | 15 | 48 | 4.00 | 96 | 111 | 115 | 80 | 45 | 45 | 75/90/100/135 | 3 | 20 | 25 | |

| SEN | 190 | 22.0 | 33.0 | 66.0 | 15.75 | 20 | 55 | 7.5 | 115 | 129 | 133 | 102 | 54 | 51 | 3 | 24 | 25 | ||

| 225 | 33.0 | 49.5 | 99.0 | 23.62 | 20 | 60 | 10.00 | 127 | 142 | 153 | 108 | 64 | 57 | 3 | 24 | 25 | |||

| 226 | 46.0 | 69.0 | 138.0 | 32.93 | 25 | 65 | 13.00 | 137 | 142 | 178 | 115 | 70 | 50 | 3 | 30 | 33 | |||

| 276 | 73.0 | 109.5 | 219.0 | 52.26 | 25 | 75 | 19.00 | 157 | 162 | 200 | 127 | 80 | 60 | 140/180 | 3 | 20 | 40 | ||

| K | 280 | 110.0 | 165.0 | 330.0 | 78.76 | 30 | 80 | 44.00 | 192 | 197 | 200 | 140 | 80 | 60 | 3 | - | 40 | ||

| KR | 295 | 180.0 | 270.0 | 540.0 | 128.88 | 30 | 90 | 50.00 | 237 | 244 | 238 | 160 | 95 | 80 | 3 | - | 48 | ||

| KN | 2955 | 300.0 | 450.0 | 900.0 | 214.8 | 30 | 100 | 55.00 | 237 | 244 | 264 | 180 | 108 | 80 | 3 | - | 48 | ||

| 300 | 434.0 | 651.0 | - | 310.74 | 30 | 100 | |||||||||||||

| 350 | 611.0 | 916.0 | - | 437.47 | 30 | 115 | |||||||||||||

This coupling type is indispensable in applications requiring reliable, continuous operation where shock and vibration are a concern:

- General-purpose electric motor drives

- Pumps and fluid-handling systems

- Light to medium-duty Compressors and Blowers

- Material Conveyors and Feeders

We offer high-quality elastomer inserts, precision hubs, and quick delivery for industrial replacements and OEM projects.