Durable Monorail Gear Trolleys For I Beam and Industrial Grade I-Beams for Overhead Material Handling.

We are a prominent Manufacturer and Supplier of high-quality Monorail Travelling Trolleys and Industrial I-Beams, the foundation for reliable overhead material handling and structural conveyance systems. Our products are manufactured from the finest raw materials, adhering strictly to national quality standards, ensuring durability and functional performance across various heavy-duty applications.

We provide the essential structural and motion components necessary to create safe, robust, and cost-effective material handling solutions in your facility.

Our Monorail Travelling Trolleys are designed for smooth and safe load movement along I-beams. As a reliable manufacturer & supplier of I-beam trolleys, we provide durable and efficient material handling solutions with adjustable fits for common beam sizes.

The I-Beam (also known as a universal beam or H-beam) is a critical linear structural component that primarily carries loads in bending.

- Economical Design: I-Beams provide economical floor and roof systems in applications requiring long, clear spans and lighter overall structural weight.

- Load Distribution: The shape (resembling the letter 'I') is engineered to provide maximum load capacity and resistance to bending stress, essential for supporting heavy machinery and trolley systems.

- Durability and Functionality: Our I-Beams are highly durable, available in various lengths and weights, and are widely recommended for use in steel-frame buildings and bridges.

Our Monorail Gear Trolleys For I Beam are designed to mount directly onto the I-Beam, facilitating the smooth, horizontal movement of attached hoists (both electric chain and wire rope types) and suspended loads.

- Smooth Travel: Engineered for reliable motion, ensuring the trolley and its load travel smoothly along the I-Beam flange.

- Versatile Use: Essential for creating flexible, linear overhead conveyance systems and bridge crane setups.

- Durability: Built to withstand constant movement and the lateral forces associated with industrial material transfer.

Our I-Beams and associated Monorail Trolley Systems are widely recommended for critical applications:

- Overhead Crane Systems: Providing the main support beam (bridge girder or runway) for hoists and bridge cranes.

- Structural Construction: Primary load-bearing elements in the construction of steel-frame buildings, factories, and industrial sheds.

- Material Handling: Creating dedicated monorail pathways for transporting materials through assembly lines and processing areas.

- Infrastructure: Used in the construction of industrial platforms and bridges.

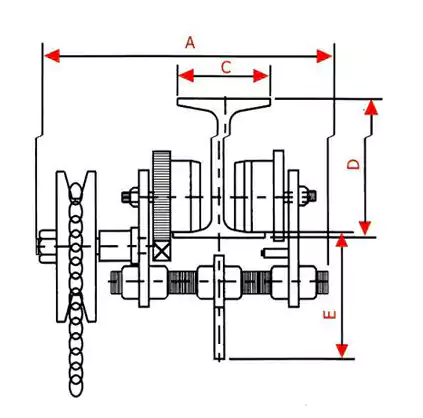

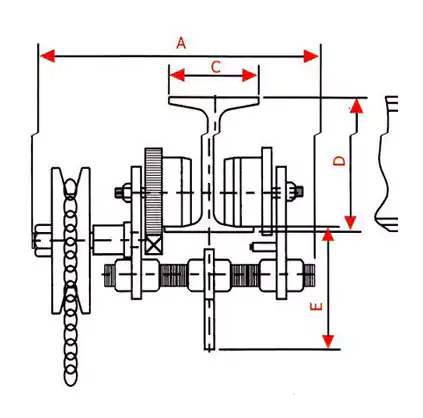

PRINCIPLE DIMENSIONS |

||||||

|

250Kg |

500 Kg |

1 TON |

2 TON |

3 TON |

5 TON |

|---|---|---|---|---|---|---|

A |

180.0 |

250.0 |

235 |

360 |

430.0 |

645.0 |

B |

169.0 |

240.0 |

240.0 |

274.0 |

346.0 |

450.0 |

C X D* |

50 X 100 |

75 X 100 |

100 X 150 |

100 X 150 |

125 X 150 |

125 X 175 |

E |

89.0 |

128.0 |

138.0 |

138.0 |

148.0 |

178.0 |

F |

15.0 |

19.0 |

26.0 |

27.0 |

25.0 |

45.0 |

G |

155.0 |

210.0 |

225.0 |

240.0 |

270.0 |

345.0 |

H X I |

24 X 34 |

33 X 48 |

46 X 60 |

45 X 60 |

46 X 65 |

58 X 75 |

We deliver customized trolley assemblies, tested wheel loads, and maintenance guidance to ensure safe operation.